Responsible value chain

We recognise that responsible consumption and production are important areas where we have the opportunity to make an impact. These areas represent some of our greatest responsibilities, extending beyond our own operations to our suppliers.

We are continuously embedding requirements into our supplier collaborations, which is essential for fulfilling our sustainability strategy and addressing key impacts such as human rights, working conditions, and greenhouse gas emissions throughout our value chain.

Supplier relationships

As part of our commitment to respecting the fundamental rights of workers in our supply chain, we became members of amfori in 2006, making us one of the first companies in Denmark to do so.

amfori is a global business association that promotes sustainable trade by assisting businesses in improving their social, environmental, and governance performance within their supply chains through:

- The amfori Business Social Compliance Initiative (BSCI)

- The amfori Business Environmental Monitoring Initiative (BEPI)

- The amfori supply chain grievance mechanism (amfori Speak for Change)

The association provides guidance and training to its members, helping them navigate the challenges arising from increasing sustainability expectations.

At JYSK, we are proud to be a member of amfori, leveraging their expertise to ensure our product suppliers meet their high social and environmental standards.

Through the Science Based Targets initiative we have a target that 72.5% of our suppliers by emissions covering purchased goods and services should have science-based targets by FY2028.

You can read more about this target and how we will work with our suppliers to reach it here >

Socially responsible production and amfori BSCI

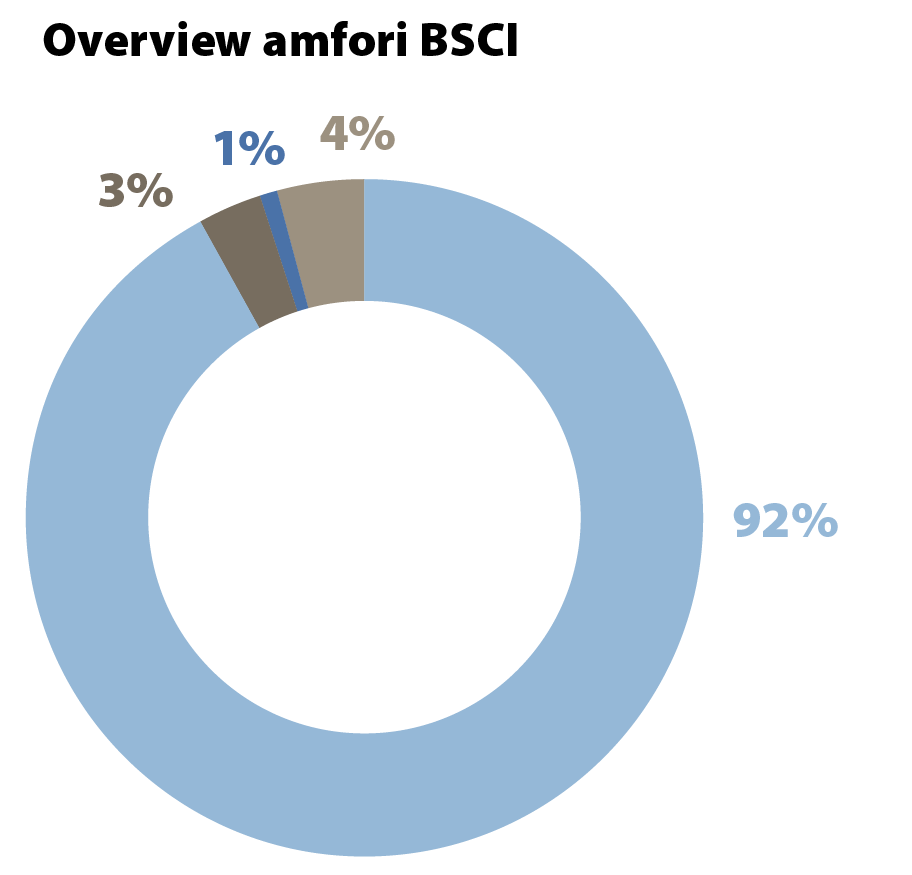

As an amfori member, JYSK can request social and environmental monitoring of our tier 1 suppliers, carried out by third-party monitoring companies. We work with amfori BSCI to have third party monitoring of manufacturers in risk countries and with amfori BEPI third party monitoring across all countries. The monitoring is divided into different thematic areas, rated from 'A' to 'E' based on how well the manufacturer meets the criteria. These ratings are then combined into an overall monitoring score.

We want all our suppliers to rank C or above. If a supplier ranks D or E, we require an action plan for how they can improve to C or higher. We believe this approach benefits workers in the value chain, as initiatives must be implemented to raise scores. This figure shows purchased volumes from suppliers as of 31.08.2025 split on audit scores.

JYSK’s products, including both items for sale and items used in store interiors, are produced in various locations worldwide. This includes so-called risk countries, which are defined as countries where there is a greater risk of non-compliance with the fundamental rights at work outlined in the International Labour Organisation’s (ILO) Declaration on Fundamental Principles and Rights at Work.

As a member of amfori BSCI, JYSK adheres to a common Code of Conduct – a set of rules that outlines specific requirements regarding the conditions in the factories where JYSK products are manufactured. The amfori BSCI Code of Conduct references international conventions such as the Universal Declaration of Human Rights, the UN Guiding Principles for Business and Human Rights, the OECD Guidelines, and the ILO's Declaration on Fundamental Principles and Rights at Work.

The amfori BSCI Code of Conduct consists of 13 principles that promote ethical and socially responsible business practices, plus JYSK’s own requirements. These principles address issues such as the prohibition of child labour, forced labour, discrimination, and corruption. The Code also includes requirements for workplace safety, reasonable working hours, and the right of factory employees to join a union and engage in collective bargaining. All manufacturers in risk countries must accept and comply with our Supplier Code of Conduct, which incorporates the 13 principles of the amfori BSCI Code.

Audit setup for amfori BSCI

Before JYSK begins collaborating with a new manufacturer in risk countries, an assessment of the working conditions at the production site is mandatory. Every production site must provide a valid third-party audit report. The audit must be completed before JYSK will start any collaboration with the site, and regular audits are conducted thereafter. The frequency of these audits depends on the findings of the previous audit.

amfori BSCI is responsible for carrying out the audits, which are conducted by impartial third-party auditors. To ensure an accurate evaluation of the production site, JYSK mandates semi-announced audits, meaning the production site is informed only of a one-month time window in which the audit will take place – but not the exact date. This ensures that the site remains prepared for inspection at any time within that period.

To further ensure reliable results, employees are randomly selected for qualitative interviews, conducted in a separate location to ensure their anonymity and comfort. Multiple employees are interviewed to provide a comprehensive view of the working conditions.

If the audit reveals any non-compliance with the Code of Conduct, the manufacturer is required to create an action plan and begin improvements immediately. A follow-up audit will be scheduled to verify that the necessary changes have been made. In cases of serious breaches, a zero-tolerance protocol is triggered. Immediate action is required to address the violation, and a remediation group is formed to create a plan for corrective measures. This group also determines appropriate remediation for the affected individuals. In such cases, the Compliance & Quality Director of JYSK is involved immediately, and the Executive Vice President of Purchasing is informed.

The day-to-day responsibility of overseeing manufacturers’ compliance with the Code of Conduct, including the protection of workers’ human rights, is based in the JYSK Compliance & Quality department, where a BSCI-responsible is appointed.

The way forward is with dialogue and involvement

When deviations from our Supplier Code of Conduct are identified at a factory, JYSK prefers to continue working with the manufacturer to ensure improvements are made. Simply ending the cooperation and turning our backs on the problems would mean that change never happens. Continuous improvement is at the heart of amfori BSCI, and at JYSK, we believe that dialogue and involvement are key to improving social conditions.

However, for future cooperation to continue, we must see measurable improvements at the factory. If progress is not made, the partnership will be terminated.

Grievance mechanism

JYSK’s membership with amfori provides access to a grievance mechanism for our business partners. amfori Speak for Change offers a platform for individuals or organisations to raise concerns about perceived or actual instances of unfair or improper treatment in our supply chain.

JYSK also offers a public whistleblower service, accessible to customers, employees, suppliers, and their employees for submitting grievances.

You can read more about it here >

Environmentally responsible production and amfori BEPI

amfori BEPI is built on the values outlined in established due diligence and environmental frameworks, such as the UN Sustainable Development Goals, the UN Guiding Principles on Business and Human Rights, and the OECD Guidelines for Multinational Enterprises on Sustainable Business Conduct.

As an international environmental management system, amfori BEPI helps businesses identify and address environmental risks within their supply chains. The environmental risk analysis covers up to eight key environmental performance areas including environmental management systems, energy and climate, water and effluents, emissions to air, waste, chemicals, biodiversity, and nuisances.

Through amfori BEPI, JYSK gains valuable insights into these environmental areas and a better understanding of our manufacturers' environmental performance.

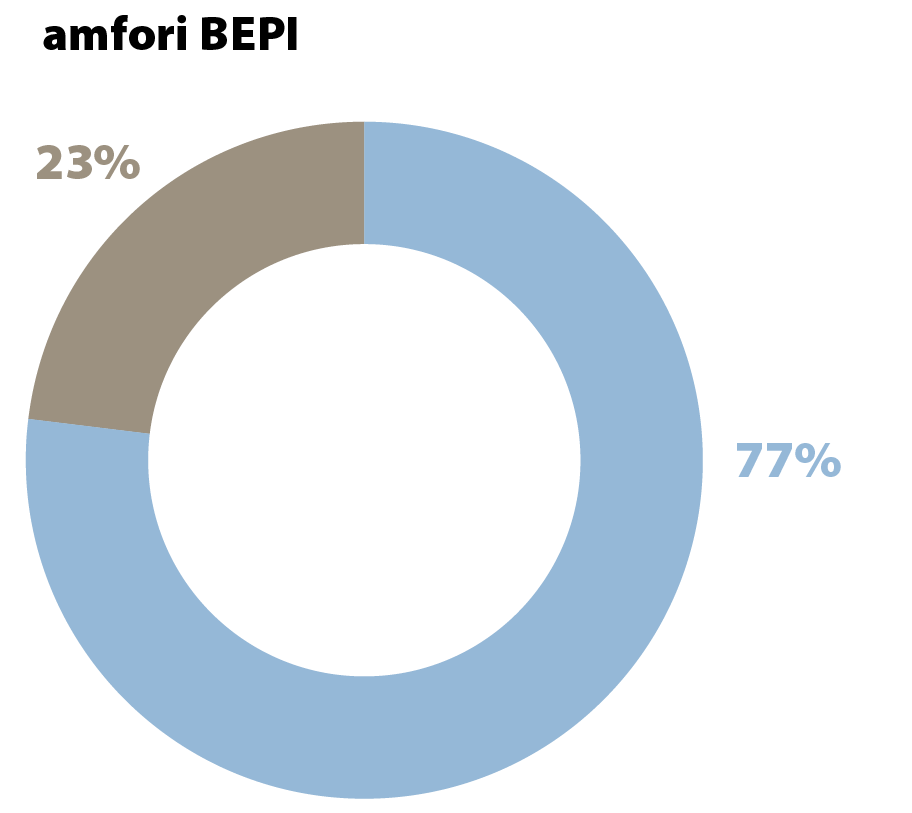

We request that our suppliers are monitored through amfori BEPI. In FY25 77% of our suppliers had a valid BEPI score. Find more information about this in our annual report.

Audit setup for amfori BEPI

Risk assessments are a core component of the amfori BEPI system. These assessments are self-declared by suppliers and can cover up to eight key environmental performance areas. In their assessments, suppliers must provide data on factors such as energy and water consumption, waste generation, and the presence of environmental management systems, among others.

The implementation of BEPI environmental monitoring for manufacturers is ongoing, encompassing all eight key environmental performance areas.

During monitoring, third-party monitoring partners verify the data provided in the risk assessments. As this involves reviewing substantial documentation, such as energy bills, water usage records, and waste production reports, BEPI monitoring is fully announced to allow manufacturers time to prepare the required information. These audits provide JYSK with relevant data on key environmental metrics from our manufacturers.

Manufacturers are expected to conduct regular audits, with the frequency of these audits determined by their previous performance results.

Supplier selection and collaboration

At JYSK, we collaborate with many suppliers across the globe. As part of maintaining our wide product range, we regularly evaluate and select new suppliers while continuously reassessing our existing partnerships.

To assist with this, we use an internal scoring tool called Supplier Performance Management (SPM). This tool evaluates suppliers based on a range of criteria, including key aspects such as order handling, claims rate, and other relevant KPIs, alongside their amfori BSCI scores.

Integrating more sustainability criteria into our supplier negotiations is essential to fostering stronger partnerships and reinforcing our commitment to sustainability as a core priority. Moving forward, we aim to give sustainability parameters even greater weight in supplier evaluations. Additionally, we continuously set clear performance expectations and audit benchmarks that our product suppliers must meet in their audits.

For more information on amfori BSCI and amfori BEPI, see the sections above.